Experimental and FEM Vibration Analysis of Impellers used for Water Pump

Keywords:

vibration, NPSH, impeller, porosity, cavitationAbstract

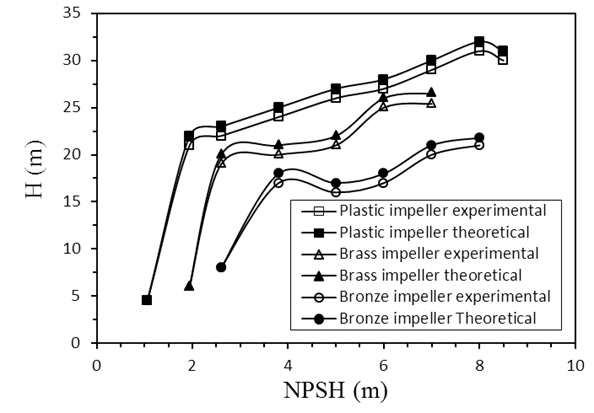

The impeller is an essential component of the water pump. Vibrations of the impeller have a significant effect on the pump's performance, as well as posing some damaging effects. In this study, the vibration of three different types of impellers for water pumps (brass, bronze, and plastic) was evaluated experimentally and compared with computational finite element method (FEM). A number of variables includes temperature, flow rate, impeller material composition, and the chemical composition of water been studied. The findings indicated that vibration issues increased as flow rate increased. The plastic impeller has the highest vibration rate compared to brass and bronze impellers under the identical testing conditions. The vibration rate of impellers tested in seawater is higher than that them tested in tap water. Increasing the temperature of the water accelerates the vibration process. Cavitation occurs in seawater at a lesser Net Positive Suction Head (NPSH) than in tap water.

Downloads

References

G. Metin and M. O. Mehmet, “Centrifugal pump design materials and specifications”, Eskisehir Technical University, Journal of Science and Technology, B-Theoretical Sciences, vol.8(1), pp.143-153, 2020.

B. P. Kamiel, “Vibration-Based Multi-Fault Diagnosis for Centrifugal Pumps”, Ph.D. thesis, Department of Mechanical Engineering, Curtin University, Australia., 2015.

P. O. Babalola, “Performance evaluation of a centrifugal pump with different impeller materials”, J. Phys. Conf. Ser., vol.1378, pp.1-13, 2019.

K. K. McKee, G. Forbes, I. Mazhar, R. Entwistle, and I. Howard, “A review of major centrifugal pump failure modes with application to the water supply and sewerage industries”, ICOMS Asset Management Conference, Asset Management Council, May - 2011, Gold Coast, QLD, Australia, 2011.

J. E. Corley, “Vibrational problems of large vertical pumps and motors”, Proceedings of the ninth Turbomachinery Symposium, Department of Mec.l Eng., Texas A & M University, Texas, USA, 1980.

B. Ravindra, Rajashri P., and Kedar K., “Vibration and noise in centrifugal pumps-sources and diagnosis methods”, 3rd Int. Conf. on Int., Rel. and Failure, Paper S1163-P0437, pp.1-12, Porto/Portugal, 20-24 July, 2009.

L. C. Tang Penghuang, “Finite element analysis of large plastic impeller”, 2010 International Conference on Computer Design and Applications, Qinhuangdao, China, 2000.

A. Albraik, Fiasal W. Althobiani, Fengshou G., and Andrew D. Ball, “Diagnosis of Centrifugal Pump Faults Using Vibration Methods”, Journal of Physics: Conference Series, vol.364(1), pp.1-14, 2012.

Muhammad A., Saravanan K., Santosh P. and Idris I., “Modal analysis of a centrifugal pump impeller using finite element method”, MATEC Web of Conferences, vol. 13, pp.04030, 2014.

M. Rakibuzzaman, S. H. Suh, H. H. Kim, Y. H. Jung, “Relationship between Cavitation Incipient and NPSH Characteristic for Inverter Drive Centrifugal Pumps”, KSFM J. of Fluid Machinery, vol.18 (6), pp.76-80, 2015.

L. Wei, Leilei Ji, Weidong Shi, Ling Zhou, Xiaoping Jiang, and Yang Zhang,V”ibration characteristics of the impeller at multi-conditions in mixed-flow pump under the action of fluid-structure interaction”, Journal of Vibroengineering vol.18(5), pp.3213-3224, 2016.

L. Jiaxing, S. Yuan, S. Parameswaran, J. Yuan, X. Ren and Qiaorui Si, “Investigation on the vibration and flow instabilities induced by cavitation in a centrifugal pump”, Advances in Mechanical Engineering, vol.9(4), pp.1–11, 2017.

C. Baoling, J. Li, C. Zhang, and Y. Zhang, “Analysis of radial force and vibration energy in a centrifugal pump”, Mathematical Problems in Engineering, pp.1-12, 2020.

Z. Alessandro, “Vision-based vibration monitoring of structures and infrastructures: an overview of recent applications” Infrastructures Journal, vol.6(4), pp.1- 22, 2021.

M. A. Hosien, S. M. Selim, “Experimental study of cavitation criterion in centrifugal pumps”, Journal of Visualization, vol.16, pp.99–110, 2013.

R. D. Joseph , “Copper and Copper Alloys”, ASM International Handbook Committee, USA, 2001.

Gonzalez V. W. and Mancini H. L., “An introduction to materials Science”, Princeton University Press, US, 2004.

C. Cho, “Determining the elastic – plastic properties of materilic material through instrument identation, Ph.D thesis, university polytechnic”, material science department, Madrid, 2016.

W. Y. Zhao, J. G. Ge, D. Ma, C. M. Li and S. B. Bao, “Vibration analysis of large centrifugal pump rotors”, IOP Conf. Series: Materials Science and Engineering, vol.52, pp.1-9, 2013.

P. Ramana, J. Suresh K., Ramana Murthy B. V., and N. S. Kumar, A” modal approach for vibration analysis and condition monitoring of a centrifugal pump”, Int. J. of Eng. Science and Technology (IJEST), 2011.

G. W. Zboinski, “Application of the three-dimensional triangular-prism hpq adaptive finite element to plate and shell analysis”, Computers & Structures vol.67(4), pp.497-514, 1997.

Y. Ryan, Rob R. and Cindy W., “Porosity analysis in porous brass using dual approaches”, American Journal of Engineering and Applied Sciences, vol.9 (1), pp.91-97, 2016.

V. Hannes, Bernadette F., and Manfred S., “The chemical composition of brass in nuremberg trombones of the sixteenth century”, Historic Brass Society Journal, vol.24, pp.61-77, 2012.

A. Gokhan, “Effect of material properties on vibrations of nonsymmetrical axially loaded thin-walled euler-bernoulli beams”, Mathematical and Computational Applications, 15(1), 96-107, 2010.

D. D. Chung, “Materials for vibrating materials”, Journal of Material Science, vol.36, pp. 5733-5737, 2001.

K. Naveen, Subhaschndra K. and Nguyen T., “Influence of porosity distribution on nonlinear free vibration and transient respons of porous functionally graded skew plate”, Defence Technology, vol.17, pp.1918-1935, 2021.

D. H. Ibrahim, P. Xue, and E. A. B. Eltahi, “Multiple salinity equilibria and resilience of persian/arabian gulf basin salinity to brine discharge”, Front. Mar. Sci., vol.7, pp1-12, 2020.

J. Carvill, Mechanical Engineer’s Data Handbook, Chapter 6, pp.2018-2066, 1993.

J. E. Mark, D”ensities, coefficients of thermal expansion, and compressibility’s of amorphous polymers”, physical properties of polymers Handbook, Springer, 2007.

Z. Xinqian, and Chuang D., “Effect of temperature and pressure on stress of impeller in axial-centrifugal combined compressor”, Advances in Mechanical Engineering, vol.8(6), pp.1–11, 2016.

J. Maziar, and Z. Amin, “Thermal effect on free vibration analysis of functionally graded arbitrary straight-sided plates with different cutouts”, Latin American Journal of Solids and Structures, vol.8, pp.245-257, 2011.

D. E. Tyler, “Wrought copper and copper alloy products, properties and selection: nonferrous alloys and special-purpose materials”, ASM Handbook, Tenth Ed. Vol.2:244, ASM International, Materials Park, OH, 1990.

A. F. Abdulsalam, M. S. Ghattas, B. A. Iskander, S. A. Ajeel, and T. A. Enab, “Structural characterization and detecting processes of defects in leaded brass alloy used for gas valves production”, Alexandria Engineering Journal, vol.57, pp.1301–1311, 2018.

J. W. Martin, Materials for Engineering, Third Edition, Chapter 3, UK, 2006.

X. Yong, C. Bo, W. Shun, N. Yi-Qing and L. X. You, “Temperature effect on vibration properties of civil structures: a literature review and case studies”, J. of Civil Structural Health Monitoring, vol.2, pp.29–46., 2012.

Downloads

Published

How to Cite

Issue

Section

ARK

License

Copyright (c) 2023 Haider Jasim

This work is licensed under a Creative Commons Attribution 4.0 International License.

Copyright on any article in the International Journal of Engineering and Applied Physics is retained by the author(s) under the Creative Commons license, which permits unrestricted use, distribution, and reproduction provided the original work is properly cited.

License agreement

Authors grant IJEAP a license to publish the article and identify IJEAP as the original publisher.

Authors also grant any third party the right to use, distribute and reproduce the article in any medium, provided the original work is properly cited.